Building a hot rod requires critical decisions that affect your budget, timeline, and satisfaction with the final product. The choice between a complete chassis and a rolling chassis ranks among the most important decisions you'll make. Understanding the differences helps you select the right foundation for your specific build requirements.

In this guide, you'll learn:

- Complete chassis vs rolling chassis key differences

- Real cost comparison and hidden expenses

- Skill requirements for each approach

- Timeline expectations from purchase to completion

- How to choose the right chassis type for your build

What's the Difference Between Complete and Rolling Chassis?

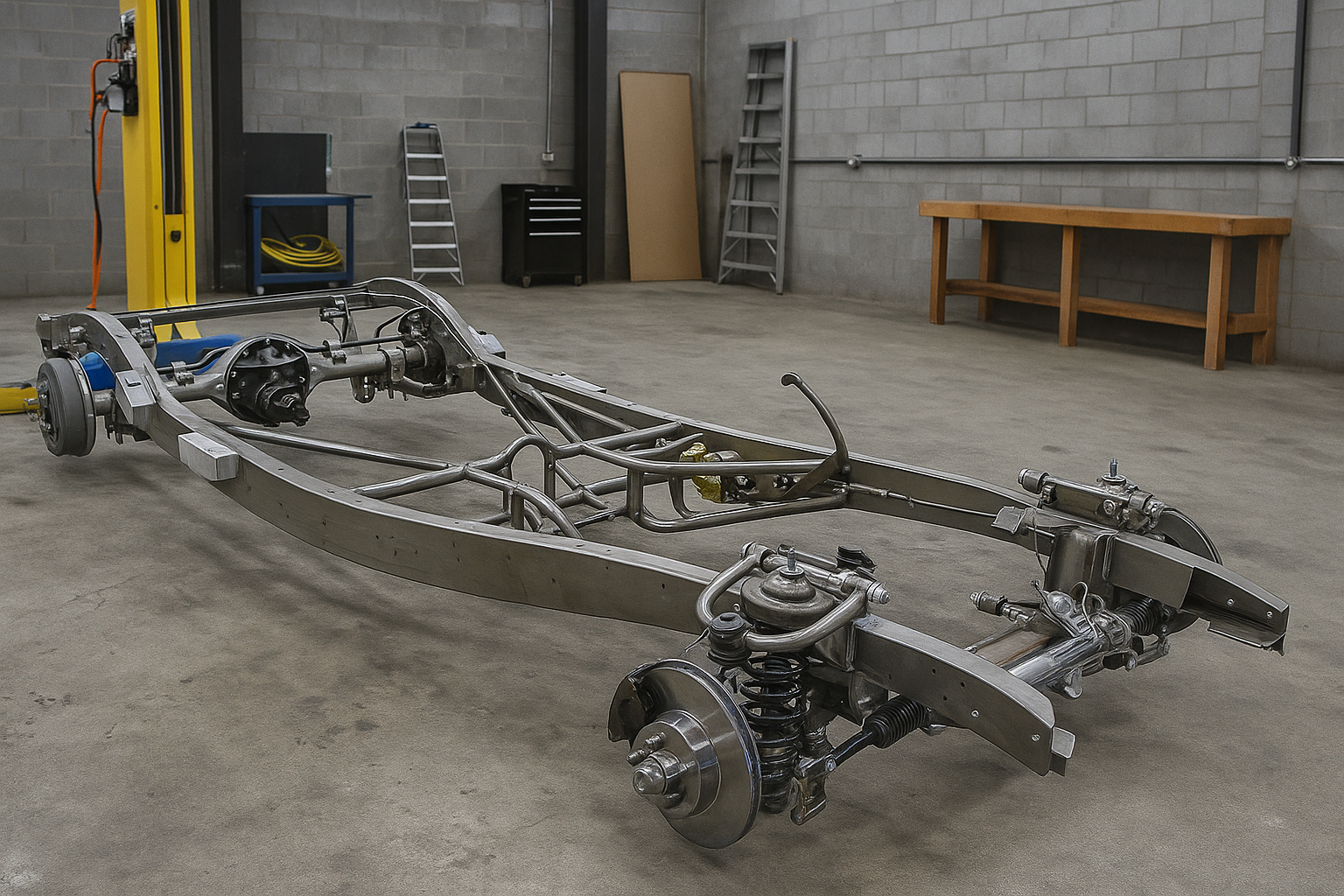

Quick Answer: Complete chassis are fully assembled rolling platforms with suspension, steering, brakes, and wheels installed. Rolling chassis provide frame rails and crossmembers only, leaving you to source and install all other components. Complete chassis cost $12,000-$25,000 and save significant build time. Rolling chassis start at $3,000-$8,000 but require additional parts and extensive labor.

Complete Chassis Characteristics

Primary purpose: Turnkey foundation for hot rod builds requiring minimal assembly

Key features:

- Fully assembled suspension systems (front and rear)

- Complete steering system installed and aligned

- Four-wheel disc brake systems with lines plumbed

- Wheels and tires mounted and balanced

- Fuel system components (tank, lines, filters)

- Professional engineering and assembly

- Model-specific design for popular hot rod platforms

- Factory testing and quality control

- Premium components from established manufacturers

Manufacturers: Roadster Shop, Art Morrison Enterprises, Schwartz Performance, TCI Engineering, Chassis Engineering

Rolling Chassis Characteristics

Primary purpose: Foundation for custom builds requiring component selection and assembly

Key features:

- Frame rails and crossmembers only

- Mounting points for suspension and drivetrain

- Lower initial cost ($3,000-$8,000)

- Complete flexibility in component selection

- Suspension components sourced separately

- Steering system purchased and installed by builder

- Brake system requires complete assembly

- Requires fabrication skills for proper installation

- Extended build timeline (6-12 weeks for chassis completion)

Available from: TCI Engineering, Chassis Engineering, Pete & Jake's, custom fabricators

How Much Does a Complete Chassis Cost?

Quick Answer: Complete chassis from reputable manufacturers range from $12,000 to $25,000 depending on specifications and included components. Fully independent suspension chassis with coilovers, power steering, four-wheel disc brakes, and premium components typically cost $18,000-$25,000. Basic complete chassis with solid rear axles start around $12,000-$15,000.

Complete Chassis Price Breakdown

Entry-Level Complete Chassis ($12,000-$15,000):

- Solid rear axle configuration

- Front independent suspension

- Manual steering or basic power steering

- Four-wheel disc brakes

- Standard wheels and tires

- Basic fuel system components

Mid-Range Complete Chassis ($15,000-$20,000):

- Independent front suspension with coilovers

- Four-link rear suspension with coilovers

- Power rack-and-pinion steering

- Upgraded disc brake systems

- Quality wheels and tires

- Complete fuel system with tank

Premium Complete Chassis ($20,000-$25,000+):

- Fully independent suspension front and rear

- Adjustable coilover systems

- Power steering with tilt column

- High-performance brake systems

- Premium wheels and tires

- Complete fuel system with baffled tank

- Wiring harness included

- Radiator and cooling components

Additional costs:

- Freight shipping: $500-$1,500

- Shipping insurance: $100-$300

- Body mounting hardware: $200-$500

- Installation labor (if hired): $2,000-$5,000

How Much Does a Rolling Chassis Cost?

Quick Answer: Rolling chassis from quality manufacturers cost $3,000-$8,000 for frame rails and crossmembers. However, total cost reaches $15,000-$22,000 once you add all necessary components (suspension, steering, brakes, wheels, fuel system). The lower entry price appeals to budget builders who can source parts over time.

Rolling Chassis Price Breakdown

Frame Only ($3,000-$8,000):

- Engineered frame rails

- Crossmember structure

- Mounting brackets and tabs

- Quality varies by manufacturer

- Boxing and reinforcement included

Components Required for Completion:

Front Suspension ($3,000-$6,000):

- Independent front suspension kit

- Coilover shocks

- Control arms and hardware

- Sway bar and links

- Spindles and hubs

Rear Suspension ($2,500-$5,000):

- Four-link kit or leaf spring setup

- Coilover or shock absorbers

- Rear axle housing (if needed)

- Panhard bar or watts link

- Hardware and mounting brackets

Steering System ($800-$1,500):

- Power rack-and-pinion unit

- Steering column

- Universal joints

- Mounting brackets

- Lines and fittings

Brake System ($2,000-$4,000):

- Four-wheel disc brake kit

- Master cylinder and booster

- Brake lines (stainless steel)

- Proportioning valve

- Hardware and fittings

Wheels and Tires ($1,500-$3,000):

- Four wheels (custom size)

- Four tires (performance compound)

- Lug nuts and hardware

- Wheel spacers if needed

Fuel System ($500-$1,500):

- Fuel tank

- Fuel pump (electric)

- Fuel lines and fittings

- Filters and regulators

- Mounting hardware

Miscellaneous Hardware ($500-$1,000):

- Fasteners and bolts

- Bushings and bearings

- Specialty tools

- Consumables (welding wire, grinding discs)

Total Rolling Chassis Cost: $13,800-$29,000

Cost Savings Strategies

Ways to reduce rolling chassis costs:

- Source used components in excellent condition

- Shop off-season sales and clearance

- Use donor vehicle components (axles, brakes)

- Buy component kits instead of individual parts

- Spread purchases over extended timeline

- Join hot rod forums for used parts marketplace

- Attend swap meets and car shows

What Skills Do You Need for a Complete Chassis?

Quick Answer: Complete chassis installation requires basic mechanical aptitude, ability to follow instructions, and competence with hand tools. No specialized hot rod building knowledge or fabrication skills required. If you can perform basic automotive service work, mount body components, and drill precise holes, you can successfully install a complete chassis.

Required Skills for Complete Chassis

Basic Mechanical Skills:

- Reading and following technical instructions

- Using measuring tools accurately (tape measure, level)

- Operating hand tools (wrenches, sockets, screwdrivers)

- Drilling holes in precise locations

- Basic fabrication (cutting, grinding, fitting)

- Torque wrench operation

Body Mounting Skills:

- Positioning body correctly on chassis

- Measuring and marking mounting locations

- Drilling mounting holes

- Fabricating body mount brackets

- Installing body mounts and hardware

- Ensuring proper body alignment

Connection and Assembly:

- Connecting fuel lines to tank

- Routing brake lines to master cylinder

- Basic electrical connections

- Installing pedal assemblies

- Mounting steering column

- Final hardware installation

What You DON'T Need:

- Suspension geometry knowledge

- Welding skills (minimal welding required)

- Brake system assembly experience

- Steering alignment expertise

- Advanced fabrication capabilities

Learning Resources

Helpful resources for complete chassis installation:

- Manufacturer installation manuals

- Video tutorials from chassis companies

- Hot rod building forums and communities

- Local hot rod club mentorship

- Professional installation services available

What Skills Do You Need for a Rolling Chassis?

Quick Answer: Rolling chassis builds demand significant technical knowledge and hands-on fabrication skills including suspension geometry understanding, welding proficiency, brake system assembly, steering installation, and alignment procedures. Expect steep learning curve for first-time builders. Mistakes in critical areas compromise safety and performance.

Required Skills for Rolling Chassis

Technical Knowledge:

- Suspension geometry principles

- Ride height calculations

- Weight distribution concepts

- Component compatibility assessment

- Brake system hydraulics

- Steering geometry and alignment

Fabrication Skills:

- MIG or TIG welding proficiency

- Cutting and grinding metal

- Drilling and tapping mounting holes

- Fabricating brackets and tabs

- Fitting components precisely

- Metal finishing and preparation

Assembly Skills:

- Suspension component installation

- Shock and coilover mounting

- Brake line fabrication and flaring

- Steering system installation

- Wheel bearing installation and adjustment

- Component alignment procedures

Specialized Tool Usage:

- Welding equipment

- Metal cutting tools (plasma cutter, cut-off wheel)

- Drill press and hand drills

- Tap and die sets

- Brake line flaring tools

- Torque wrenches and specialty sockets

Problem-Solving Abilities:

- Diagnosing fit issues

- Modifying components for clearance

- Creating custom mounting solutions

- Troubleshooting assembly problems

- Making engineering decisions

When Rolling Chassis Makes Sense

Ideal candidates for rolling chassis builds:

- Experienced fabricators with welding skills

- Hot rodders building unusual or highly custom designs

- Builders who enjoy hands-on fabrication work

- Those with extensive automotive knowledge

- People with unlimited timelines and patience

- Builders seeking maximum customization

- Those with well-equipped home shops

Not recommended for:

- First-time hot rod builders

- Builders with limited fabrication experience

- Those without welding skills

- Builders on tight timelines

- People without proper tools and workspace

- Builders prioritizing driving over building

How Long Does a Complete Chassis Build Take?

Quick Answer: Complete chassis installation takes 2-4 weeks from delivery to having your body mounted on a rolling chassis, assuming proper preparation and steady work schedule. Engine and transmission installation adds 2-3 weeks. Total time from complete chassis delivery to running vehicle typically ranges 8-12 weeks for organized builders.

Complete Chassis Timeline

Week 1-2: Initial Setup and Body Mounting

- Unpack and inspect chassis

- Position chassis in workspace

- Perform initial measurements

- Mock up body on chassis

- Mark mounting locations

- Fabricate body mount brackets

- Drill mounting holes

- Install body mounts

Week 3-4: Final Chassis Connections

- Connect fuel system to tank

- Route brake lines to master cylinder

- Install pedal assemblies

- Mount steering column

- Connect throttle linkage

- Test wheel clearances

- Final alignment checks

Week 5-7: Drivetrain Installation

- Prepare engine and transmission

- Install motor mounts

- Lower engine into chassis

- Connect transmission to driveshaft

- Install headers and exhaust

- Connect cooling system

- Mount accessories

Week 8-12: Final Assembly

- Complete electrical wiring

- Install interior components

- Connect all remaining systems

- Fluid fills and bleeding

- Initial startup and testing

- Troubleshooting and adjustments

Factors That Speed Up Timeline:

- Well-prepared body (already painted and ready)

- Engine and transmission pre-assembled

- Clean, organized workspace

- Helper assistance available

- All parts and hardware on hand

- Prior hot rod building experience

Factors That Slow Down Timeline:

- Body requires preparation or modification

- Engine needs building or rebuilding

- Parts ordering delays

- Limited workspace or tools

- Solo builder (no assistance)

- Learning curve for new builders

How Long Does a Rolling Chassis Build Take?

Quick Answer: Rolling chassis builds require 6-12 weeks just for chassis completion (installing suspension, steering, brakes) before body mounting begins. Total project timeline from rolling chassis delivery to running vehicle ranges 6-12 months for experienced builders. First-time builders should expect 12-24 months depending on complexity and time availability.

Rolling Chassis Timeline

Month 1-2: Component Sourcing

- Research component options

- Compare specifications and prices

- Order suspension components

- Order steering system

- Order brake system

- Order wheels and tires

- Wait for delivery of all parts

Month 2-3: Front Suspension Installation

- Mock up suspension geometry

- Fabricate mounting brackets

- Install control arms

- Mount coilovers or shocks

- Install spindles and hubs

- Install sway bar

- Install steering components

Month 3-4: Rear Suspension Installation

- Determine rear suspension configuration

- Fabricate four-link brackets

- Install rear axle or IRS

- Mount coilovers or shocks

- Install panhard bar or watts link

- Check ride height and geometry

- Final adjustments and welding

Month 4-5: Brake System Assembly

- Install brake calipers and rotors

- Fabricate brake line routing

- Flare and install brake lines

- Mount master cylinder and booster

- Install proportioning valve

- Bleed brake system

- Test brake operation

Month 5-6: Wheels, Fuel, and Final Chassis

- Mount wheels and tires

- Check clearances throughout suspension travel

- Fabricate and install fuel tank

- Route fuel lines

- Install fuel pump and filters

- Test all chassis systems

- Paint or coat exposed components

Month 6-12: Body, Drivetrain, and Completion

- Mount body on chassis (2-3 weeks)

- Install drivetrain (4-6 weeks)

- Complete electrical system (3-4 weeks)

- Interior installation (2-3 weeks)

- Final assembly and testing (2-3 weeks)

- Troubleshooting and adjustments (1-2 weeks)

Common Timeline Killers:

- Component compatibility issues requiring returns

- Fabrication mistakes requiring rework

- Learning curve for unfamiliar processes

- Tool and equipment acquisition delays

- Workspace limitations slowing progress

- Loss of motivation during extended timeline

- Budget constraints pausing work

Which Chassis Type Should You Choose?

Quick Answer: Choose a complete chassis if you have budget available now ($12,000-$25,000), want to minimize build time, lack advanced fabrication skills, or have specific deadlines. Choose a rolling chassis if you have fabrication experience, enjoy hands-on building, can spread costs over time, want maximum customization, or have unlimited timeline.

Choose a Complete Chassis If You:

Have the Budget:

- Can afford $12,000-$25,000 upfront

- Want predictable, all-inclusive pricing

- Prefer financing one large purchase

- Value time savings over cost savings

Prioritize Time:

- Want to finish build quickly (8-12 weeks possible)

- Have deadline (car show, event, anniversary)

- Limited time available for building

- Want to drive sooner rather than later

Match Skill Level:

- Basic mechanical aptitude only

- No welding or advanced fabrication skills

- First-time hot rod builder

- Prefer professional assembly and engineering

Want Simplicity:

- Don't want to research individual components

- Prefer turnkey solution

- Want tested, proven combinations

- Value warranty and support

Choose a Rolling Chassis If You:

Have Fabrication Skills:

- Experienced welder (MIG or TIG)

- Comfortable with metal fabrication

- Understand suspension and steering geometry

- Can troubleshoot mechanical issues

Enjoy Building:

- Find satisfaction in hands-on work

- Want to complete more of build yourself

- Learn by doing

- Take pride in custom fabrication

Have Flexible Budget:

- Can spread purchases over 6-12 months

- Want to hunt for deals and used components

- Have more time than money

- Can absorb costs gradually

Want Customization:

- Building unusual or unique platform

- Want specific component combinations

- Need non-standard configurations

- Prefer component selection freedom

Have Unlimited Timeline:

- No deadline pressure

- Building for enjoyment, not completion

- Can work at your own pace

- Patient with extended process

What Are Common Complete Chassis Mistakes?

Quick Answer: Common complete chassis mistakes include improper body positioning, incorrect mounting hole placement, ignoring manufacturer instructions, skipping test fitting procedures, and attempting modifications without understanding engineering. Most mistakes result from rushing installation or failing to measure twice before drilling permanent holes.

Installation Mistakes

1. Poor Body Positioning

- Not centering body on chassis properly

- Incorrect ride height resulting in tire clearance issues

- Body rake angle not considered

- Door gaps and body panel alignment ignored

2. Mounting Hole Errors

- Drilling before thorough measuring and marking

- Using improper drill bit sizes

- Not deburring holes causing stress points

- Missing crucial mounting locations

3. Ignoring Instructions

- Skipping manufacturer installation manual

- Assuming installation without reading procedures

- Not following torque specifications

- Improvising instead of following guidelines

Component Connection Mistakes

4. Fuel System Issues

- Using incorrect fuel line sizes

- Improper fuel line routing (heat exposure)

- Missing fuel filter installation

- Inadequate line securing and support

5. Brake Line Problems

- Routing brake lines near heat sources

- Not supporting lines properly

- Mixing line types (rubber and stainless)

- Improper master cylinder mounting

6. Electrical Errors

- Not following wiring diagrams

- Using incorrect wire gauges

- Poor connection quality

- Missing fuses and circuit protection

Planning Mistakes

7. Insufficient Preparation

- Body not ready before chassis arrival

- Missing necessary hardware and parts

- Inadequate workspace setup

- Tools not available when needed

8. Unrealistic Expectations

- Underestimating installation time required

- Assuming zero modifications needed

- Expecting perfect fit without test fitting

- Not budgeting for minor fabrication needs

What Are Common Rolling Chassis Mistakes?

Quick Answer: Common rolling chassis mistakes include purchasing incompatible components, poor suspension geometry causing handling issues, brake system failures from improper assembly, weak or incorrect welding on critical mounts, and underestimating time and skill requirements. Safety compromises result from mistakes in critical areas.

Component Selection Mistakes

1. Incompatible Parts

- Mixing components from different manufacturers without checking compatibility

- Wrong bolt patterns or mounting dimensions

- Suspension components not designed for chassis

- Steering components not matching suspension geometry

2. Cheap Components

- Buying lowest-priced parts regardless of quality

- Using untested offshore components

- Mixing quality levels (premium front, cheap rear)

- Ignoring brand reputation and reviews

3. Wrong Specifications

- Incorrect spring rates for vehicle weight

- Wrong shock lengths for suspension travel

- Brake components undersized for vehicle

- Steering ratio not appropriate for application

Fabrication and Installation Mistakes

4. Poor Welding

- Insufficient penetration on critical joints

- Inadequate weld size for loads

- Welding in wrong locations

- Not cleaning and preparing surfaces

5. Suspension Geometry Errors

- Incorrect control arm angles causing binding

- Wrong instant center locations

- Anti-squat or anti-dive set incorrectly

- Ride height outside designed range

6. Brake System Failures

- Improper brake line flaring technique

- Wrong proportioning valve settings

- Air in brake lines from poor bleeding

- Mixing incompatible brake fluids

7. Steering Issues

- Bump steer from incorrect tie rod angles

- Excessive steering effort from wrong ratio

- Play in steering system from poor installation

- Alignment impossible due to design errors

Project Management Mistakes

8. Timeline Underestimation

- Assuming 2-3 months sufficient for completion

- Not accounting for learning curve

- Underestimating component sourcing time

- Ignoring inevitable setbacks and problems

9. Budget Miscalculation

- Only considering frame cost, not total components

- Not budgeting for tools and equipment

- Underestimating consumables and hardware

- No contingency for mistakes and rework

10. Skill Overestimation

- Attempting beyond current capabilities

- Not seeking help when needed

- Ignoring safety in critical areas

- Learning on parts that matter most

Can You Upgrade a Rolling Chassis Later?

Quick Answer: Yes, rolling chassis accept upgrades and modifications more easily than complete chassis because you install components yourself and understand the system. Common upgrades include better shocks, upgraded brake systems, power steering conversions, and adjustable suspension components. Changes require mechanical skills but cost less than complete chassis modifications.

Common Rolling Chassis Upgrades

Suspension Improvements:

- Upgrading to adjustable coilovers from fixed shocks

- Adding sway bars for improved handling

- Installing adjustable control arms for alignment flexibility

- Upgrading bushings to polyurethane or spherical bearings

Brake System Upgrades:

- Converting to larger diameter rotors

- Upgrading to multi-piston calipers

- Installing adjustable proportioning valve

- Adding residual pressure valves

Steering Enhancements:

- Converting manual steering to power steering

- Upgrading to quick-ratio steering box

- Installing tilt steering column

- Adding power steering cooler

Ride Quality Changes:

- Different spring rates for comfort or performance

- Upgraded shock valving for better control

- Air suspension conversion for adjustability

- Electronic suspension management systems

Upgrade Advantages of Rolling Chassis

Why rolling chassis accept upgrades more easily:

- Builder understands system from installation

- Component access easier (familiar with layout)

- Modifications don't void manufacturer warranty (no warranty to void)

- Custom fabrication already part of build

- Cost savings by doing work yourself

Can You Upgrade a Complete Chassis Later?

Quick Answer: Yes, but complete chassis modifications cost more and require more expertise because you're changing engineered systems. Common upgrades include shock rebuilds, brake pad upgrades, and wheel changes. Major modifications (suspension geometry changes, brake system overhauls) require understanding original engineering or risk compromising performance and safety.

Common Complete Chassis Upgrades

Minor Upgrades (Easy):

- Shock rebuilds or revalving

- Brake pad compound changes

- Different wheels and tires

- Sway bar adjustments

- Alignment adjustments

Moderate Upgrades (More Complex):

- Upgraded brake rotors and calipers (same mounting)

- Coilover spring rate changes

- Power steering fluid cooler addition

- Upgraded master cylinder

- Better brake lines (braided stainless)

Major Upgrades (Expensive/Complex):

- Complete suspension geometry changes

- Converting rear suspension type (solid axle to IRS)

- Major brake system overhaul

- Steering system replacement

- Chassis reinforcement or modification

Upgrade Challenges with Complete Chassis

Why complete chassis modifications cost more:

- Engineered as complete system (changing one part affects others)

- May void manufacturer warranty

- Requires understanding original engineering

- Professional installation often recommended

- Higher component costs for premium systems

- Less familiar with system (didn't build it yourself)

What About Hybrid Approaches?

Quick Answer: Hybrid approaches combine rolling chassis flexibility with some pre-assembled components, offering middle ground on cost, time, and skills. Options include partially assembled chassis (front suspension complete, rear left for builder), rolling chassis plus complete component kits, or complete chassis with planned custom modifications.

Hybrid Option 1: Partially Assembled Chassis

What you get:

- Front suspension fully assembled and aligned

- Rear suspension left for customization

- Steering system installed

- Brake system partially complete

- Rolling on wheels

Advantages:

- Saves time on complex front suspension

- Retains rear suspension flexibility

- Lower cost than complete chassis

- Less fabrication skill required

- Faster than full rolling chassis build

Best for:

- Builders wanting custom rear suspension (four-link vs leaf spring)

- Those with moderate fabrication skills

- Builders using custom rear axle

- Projects needing specific rear end configuration

Cost: $8,000-$15,000 depending on configuration

Hybrid Option 2: Rolling Chassis Plus Component Kits

What you get:

- Rolling chassis frame

- Complete suspension kits (front and rear)

- Steering kit designed for chassis

- Brake kit with all components

- Installation instructions

Advantages:

- Components guaranteed compatible

- Comprehensive instructions included

- Still perform assembly yourself

- Learn during build process

- Costs less than complete chassis

- Avoid component research and compatibility issues

Best for:

- First-time builders with basic fabrication skills

- Those wanting hands-on experience

- Builders on moderate budgets

- Projects needing guidance but not full assembly

Cost: $10,000-$18,000 for chassis and all kits

Hybrid Option 3: Complete Chassis With Planned Modifications

What you get:

- Complete chassis initially

- Plan for future upgrades

- Start driving sooner

- Upgrade as budget and skills allow

Advantages:

- Get on road quickly with complete chassis

- Learn system while driving

- Spread upgrade costs over time

- Make informed decisions based on driving experience

- No pressure to get everything perfect initially

Best for:

- Builders wanting to drive sooner

- Those planning specific upgrades later

- Budget builders with phased approach

- People wanting to learn system before modifying

Initial Cost: $12,000-$25,000, upgrades added over time

How Do You Choose Quality Manufacturers?

Quick Answer: Quality chassis manufacturers have proven track records, extensive customer reviews, engineering documentation, proper warranties, and responsive customer support. Research thoroughly on hot rod forums, read build threads showing real-world results, contact manufacturers with questions, and verify components meet industry standards before purchasing.

Complete Chassis Quality Indicators

Established Manufacturers:

- 10+ years in business

- Extensive customer base and reviews

- Recognized name in hot rod community

- Active at major car shows and events

- Professional facilities and staff

Engineering Documentation:

- Detailed installation manuals

- Technical specifications published

- Load ratings and testing data

- Suspension geometry information

- Component specifications listed

Quality Components:

- Name-brand suspension components (QA1, RideTech, etc.)

- Professional-grade brake systems (Wilwood, Baer, etc.)

- Quality steering components (Flaming River, Borgeson, etc.)

- Premium fasteners and hardware

- Proper powder coating or finishing

Customer Support:

- Technical support available

- Responsive to questions and concerns

- Installation assistance offered

- Troubleshooting help provided

- After-sale support continues

Warranty Coverage:

- Minimum 1-year warranty on complete chassis

- Component warranties honored

- Clear warranty terms published

- Reasonable return policy

- Stands behind product quality

Rolling Chassis Quality Indicators

Frame Quality:

- Proper steel specifications (2x3, 2x4 tubing sizes)

- Quality welding throughout

- Boxing and reinforcement in stress areas

- Proper powder coating or finishing

- Mounting brackets and tabs included

Engineering:

- Suspension mounting points at correct locations

- Drivetrain mounting considerations

- Body mounting provisions included

- Frame width appropriate for body style

- Proper ride height engineered

Reputation:

- Positive reviews from actual builders

- Build threads showing successful installations

- Forum recommendations

- Multiple successful builds completed

- Minimal complaints or issues reported

Red Flags to Avoid

Warning signs of poor quality:

- No verifiable customer reviews or builds

- Extremely low prices compared to established brands

- Poor communication or customer service

- No warranty or unreasonable terms

- Vague specifications or documentation

- Unknown component brands throughout

- Recent business with no track record

- Negative reviews about quality or service

- Unwillingness to answer technical questions

Final Recommendations

For First-Time Hot Rod Builders:

- Start with complete chassis ($12,000-$25,000) from established manufacturer

- Focus energy on other build aspects (body, interior, wiring)

- Learn hot rodding fundamentals without fabrication pressure

- Consider hybrid option with component kits if budget tight

- Join local hot rod club for mentorship and guidance

- Don't attempt rolling chassis without fabrication experience

For Experienced Fabricators:

- Rolling chassis ($3,000-$8,000) provides maximum customization

- Budget total project cost ($15,000-$25,000 including components)

- Enjoy fabrication process and hands-on building

- Accept extended timeline (6-12 months for chassis completion)

- Source quality components, don't cheap out on critical parts

- Consider complete chassis if deadline exists

For Budget-Conscious Builders:

- Rolling chassis allows spreading costs over time

- Hunt for used components in excellent condition

- Join hot rod forums for parts marketplace access

- Attend swap meets and shows for deals

- Budget minimum $15,000 total (don't underestimate)

- Accept that time investment is substantial

For Builders With Deadlines:

- Complete chassis only realistic option

- Plan 8-12 weeks from chassis delivery to running vehicle

- Have body prepared before chassis arrives

- Gather all parts and hardware in advance

- Consider professional assistance for complex tasks

- Budget for shipping and potential modifications

Universal Principles:

- Research manufacturers thoroughly before purchasing

- Be honest about skill level and time availability

- Budget realistically including hidden costs

- Quality matters more than initial price

- Join hot rod community for support and advice

- Don't compromise safety for cost savings

- Plan build carefully before committing money

- Remember, the goal is finishing a safe, reliable hot rod

Your chassis decision affects everything downstream in your build. Take time to assess your situation honestly, choose appropriate option for your skills and budget, and commit to seeing the project through. Whether you select a complete chassis for convenience or a rolling chassis for customization, quality components and proper assembly create the foundation for years of hot rod enjoyment.

Shop Hot Rod Chassis Components at Hot Rod Hardware

Browse All Chassis Components →

Hot Rod Hardware carries comprehensive selection of chassis components, suspension systems, steering components, and brake systems for hot rod builds. Whether you're completing a rolling chassis or upgrading a complete chassis, we stock quality parts from trusted manufacturers.

Our Product Selection:

- Suspension components (coilovers, control arms, sway bars)

- Steering systems (rack-and-pinion, columns, u-joints)

- Brake systems (calipers, rotors, master cylinders)

- Chassis hardware and fasteners

- Wheels and wheel accessories

- Frame connectors and reinforcements

Why Choose Hot Rod Hardware:

- Extensive inventory of performance parts

- Quality components from established brands

- Competitive pricing for serious builders

- Expert guidance on component selection

- Fast shipping nationwide

- Real hot rodders helping hot rodders

Need help selecting chassis components or planning your build? Contact our hot rod specialists at 877-291-0363.