Key Takeaways:

- Brake boosters use vacuum from the engine intake to multiply the force you apply to the brake pedal, making brakes easier to operate.

- Vacuum-operated boosters are common on older vehicles, while hydraulic brake boosters are used on newer models with less available vacuum.

- Properly maintaining and adjusting the brake booster is critical for safe, effective braking on hot rods and classic cars.

- Upgrading to a larger diameter booster can provide extra braking assistance for heavier hot rods.

The Importance of Brake Boosters

For hot rodders building or restoring classic muscle cars and vintage rides, having confidence in your braking system is crucial for safe performance. A properly functioning brake booster is an often overlooked but absolutely essential component when it comes to smooth, reliable braking. So how exactly do these unsung heroes operate?

How Boosters Multiply Braking Force

At its core, a brake booster's job is to amplify the relatively small amount of force applied to your brake pedal into much more powerful hydraulic pressure at the calipers or wheel cylinders. This force multiplication makes it possible to stop your ride effectively without having to mash down on the pedal like you're trying to kick through a brick wall.

Vacuum vs Hydraulic Boosters

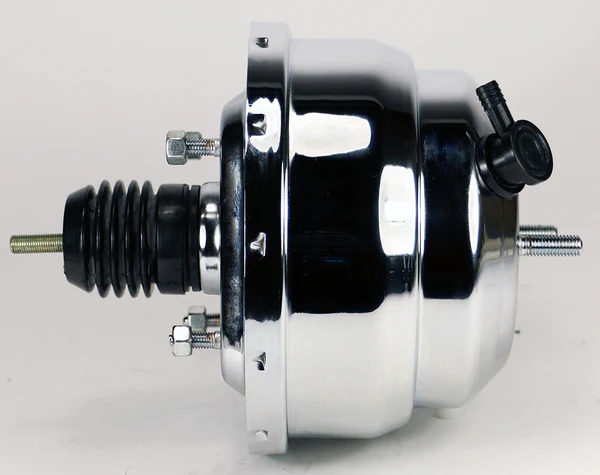

The most common type found on older vehicles is the vacuum-operated brake booster. This unit contains a diaphragm dividing it into two chambers. One chamber connects to engine vacuum from the intake manifold, while the other is open to atmospheric pressure. When you depress the brake pedal, a valve opens to allow atmospheric pressure into the vacuum chamber. The differential between this pressure and the engine vacuum generates a push force that gets amplified through a simple mechanical linkage to the master cylinder.

On vehicles from the 1960s and earlier with carbureted engines, there's typically plenty of available vacuum to operate the brake booster. However, as emission controls were introduced, involving vented vacuum systems, some later model muscle cars had inadequate vacuum sources to power the booster reliably. This led to dicey situations of total brake failure if vacuum was lost. That's one reason why hydraulic brake boosters, driven by power steering pressure rather than engine vacuum, became more prevalent on late model cars.

Booster Brands for Your Hot Rod

When it comes time to replace the brake booster on your project, Hot Rod Hardware has you covered with units from top brands like Master Power Brakes, Allstar Performance. Hydroboosts or Electric-Hydraulic controllers are available as well by Sweeting Performance. Whether you need a traditional vacuum booster or a hydraulic unit for a late model engine swap, we carry a wide selection to fit your chassis and performance needs.

Booster Maintenance

Whether you have the traditional vacuum type or a hydraulic unit, the key to optimal brake booster operation is maintaining the integrity of the vacuum or hydraulic circuits. For vacuum boosters, check for any leaks or disconnected hoses in the plumbing between the booster, intake manifold, and sources of vacuum. Cracked or deteriorated vacuum hoses and connectors are common problems that can lead to a spongy, fading brake pedal.

Proper adjustment of the booster pushrod is also critical to prevent excessive free play in the pedal before the brakes start to apply. Most boosters have a thin gasket where the pushrod exits the booster shell – as this gasket compresses over time, the pushrod must be adjusted outward to compensate.

Signs of Trouble & Replacements

Because brake boosters are a relatively inexpensive part, it's often wise to simply replace an older unit that is beginning to cause issues. Signs of a failing booster include excessive brake pedal travel, brakes not releasing readily, or complete loss of booster assistance. In some cases, a larger diameter or Dual-Diaphragm aftermarket booster can provide welcome extra braking power for a heavily modified hot rod.

Never Neglect Your Booster

Finally, never take your brake booster for granted just because it's quietly doing its job out of sight. Excessive corrosion, failed diaphragms, or contaminated vacuum lines can lead to catastrophic failure, so inspect and keep up with any needed maintenance during every rebuild or as part of your regular chassis service.

With the force-multiplying assistance of a properly operating brake booster, even the biggest performance machines with big brake upgrades can be slowed down securely and controllably. Pay attention to this vital hydraulic helper, and it will give you years of confidence when you need to drop anchor in a hurry.