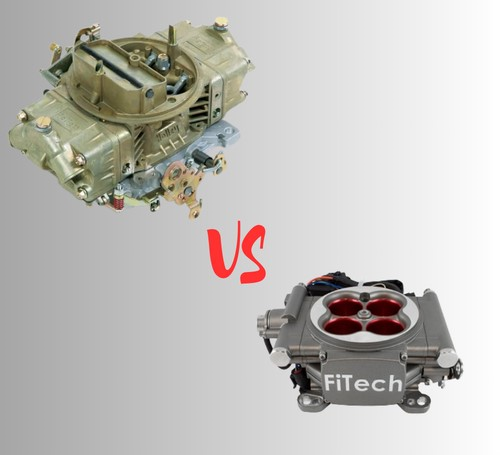

The question of carburetors versus fuel injection is one that has long divided the hot-rodding community. Both systems have their passionate defenders and detractors, with compelling cases to be made on both sides. As products like Holley's Sniper system blur the lines, the debate rages on. In this article, we’ll break down the key pros and cons, components, and capabilities of both options to help you decide which one is right for your build.

Key Takeaways:

- Carburetors are simpler and cheaper, but fuel injection delivers more consistent performance. The choice often comes down to budget and goals.

- Key parts of a carburetor system include the carb itself, intake manifold, fuel lines, fuel pump, and ignition system.

- Key parts of a fuel injection system include the throttle body/fuel injectors, ECU, sensors, wiring harness, intake manifold, and fuel system components.

- With precision digital control, fuel injection can optimize fuel mapping and adapt to modifications. Carb tuning is more trial-and-error.

- Upgrading or altering an existing fuel injection system takes more specialized knowledge compared to swapping carbs.

When building a new hot rod project, one of the most impactful engine configuration decisions you’ll make is how you’ll handle the fuel delivery. And if it’s performance you’re after, two viable options rise to the top -- good old carburetion or modern electronic fuel injection. Both can be tuned to make serious power, but they go about it in very different ways. Your budget, goals, and appetite for complexity may dictate which direction you take your build.

Carburetors - Simple and Straightforward

The basic operating concept behind a carburetor is elegantly simple – meter fuel flow by allowing intake vacuum to siphon fuel through tiny jets and passages. Brands like Edelbrock or Holley have refined carb designs into exceptionally tunable high-performance powerhouses.

The beauty of a carb lies primarily in its simplicity. With some basic mechanical aptitude and tuning knowledge, an enthusiast can bolt a carb onto an engine and get it running smoothly with a minimal number of auxiliary components. All that’s generally required is a proper intake manifold, fuel lines, mechanical or low-pressure electric fuel pump, ignition system upgrades, and possibly headers.

Of course, dozens of parameters from fuel bowl levels to primary venture sizing can be endlessly tweaked in the quest for optimal performance. So, while carburetors may be simple in concept, that doesn’t make them entirely straightforward or easy to tune. Bigger isn’t always better either when it comes to carb sizing – too much flow capacity can kill throttle response.

In terms of drivability, carburetors require careful recalibration any time major engine modifications are made. And their performance is impacted by factors like fuel pressure changes or vacuum leaks. Still, carbs provide very responsive “seat of the pants” control and tuning possibilities to match nearly any engine combo or budget. Just be prepared for some trial and error dialing it all in.

Fuel Injection – Precisely Programmable Performance

The key advantage fuel injection provides is digital control precision. By utilizing an ECU (engine control unit) and array of sensors feeding back operating parameters in real time, fuel injectors can meter precise quantities of fuel continuously. This allows fuel curves to be optimally mapped based on factors like RPM, throttle position, air temperature, etc. Brands like FiTech have radically simplified EFI swaps while still delivering this level of tuning potential.

The core components of a fuel injection system include the throttle body assembly housing the injectors, an ECU calibrated with appropriate fuel maps, oxygen sensors providing closed loop feedback, a high-pressure fuel system, and various sensors indicating parameters like coolant temp, throttle position, RPMs, etc. This all connects to the engine management computer via a main wiring harness.

With all these inputs, the system can provide essentially perfect air/fuel ratios adaptively across all operating conditions. This leads to excellent drivability, economy, and consistently maximal power output up to the engine’s peak capability. Any modifications like camshafts, intakes, or boost increases can be quickly tuned by altering the base fuel map settings alone in many cases.

The flip side is this level of precision comes with complexity. Tuning requires specialized software and diagnostic tools. While EFI systems are becoming increasingly user friendly, the learning curve is steeper compared to grabbing a screwdriver and carb tuning by ear. On a tight budget, a basic carburetor setup can often be the more pragmatic choice.

EFI Swaps Simplified

The good news for rodders is aftermarket EFI systems have become downright affordable and trouble free to install. Holley raised eyebrows when it introduced its “Sniper” systems boasting self-tuning capabilities right out of the box. Just bolt it up with a few critical sensors, press “start”, and let the ECU automatically tune itself as you drive around. Of course, the option to fine tune manually is still there and usually a required part of the process, but this breakthrough helps fuel injection compete cost-wise with basic carb setups.

So which way should you go on your next project? There’s truly no definitively “right” answer that applies across the board. Prioritize your budget, goals, appetite for complexity, and aesthetic tastes. In many cases, an argument can still be made for the irresistible sights, sounds, and hands-on tinkering carburetors invite. But there’s no denying precisely metered EFI yields quantifiably superior performance potential. Like so many things in the hot-rodding sphere, “modern” doesn’t necessarily mean better across the board. This debate is sure to continue raging for decades on!